“Oil and water don’t mix” is a common saying and a scientific fact. But oil and moisture do mix! So how is it that moisture, which is also water, can mix with oil?

Why do I mention this?

Because I tuned into a webinar last week with a title that caught my attention, “Moisture in Transformer Oil”, to find out this is something that is very important to know about, if we want to keep our lights on!

Vaisala’s webinar

The webinar was hosted by the American company Vaisala, who sell a wide range of weather instrumentation and equipment for industrial monitoring of various gases, including moisture. As part of their product range they have sensors for measuring moisture that are placed in direct contact with industrial oils. Movement of moisture into, and out of oil, can be followed using these sensors. In very simple terms, oil can be seen to become “damp”, and conversely, it can also be seen to lose moisture and become drier. Steven Jiroutek from Vaisala presented a very good webinar on a difficult subject. He showed good technical data to get across the message that measuring moisture in oil is not straightforward. But with the right technology, fluctuating levels of moisture in oil can be measured and managed.

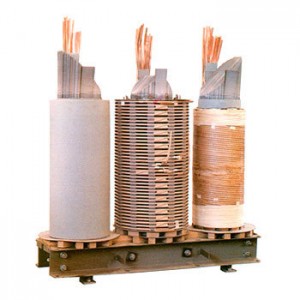

Tara Power Transformer

Power transformers

Transformer oil is, as its name suggests, an oil that is used inside power transformers. Electricity coming into our homes has to be lowered in voltage for our use. This happens at the local transformer that takes in the very high voltage electricity from the generating stations and “transforms” it to a lower voltage for local distribution. Inside the transformer are many coils of wire that sit in a tank of transformer oil that is being continually circulated. Transformer oil does not conduct electricity and insulates the different coils from each other to prevent short circuits. Transforming electricity generates heat and transformer oil also acts a coolant. Problems arise when moisture builds up in the oil. Water molecules are capable of carrying an electrical charge and, if enough are present, electricity will “leap” across the molecules causing “arcing”. Unwanted movement of electricity inside the transformer causes damage and can be critical, leading to power shutdown.

Sources of moisture in transformer oil

So how does moisture get into the oil? As I explain in my book A Wet Look At Climate Change, most materials interact with moisture, including oils. One source is from the air. Oil exposed to the air during construction of the transformer, or during maintenance, will attempt to come to equilibrium with the moisture in the air. To what extent this happens depends on the relative humidity of the air and the type of oil. Different oils interact to different extents with moisture. As Steven described in his webinar, they have different “saturation points”, which means they can hold different amounts of moisture. It gets complicated because the saturation point changes with temperature. “You must always consider the temperature” (chapter 1, A Wet Look At Climate Change).

Power transformer coils

Another source of moisture comes from paper that is wrapped around the transformer coils to insulate them from each other. Paper naturally absorbs moisture from the air in the same way as I described in my article “Wooden problem”. Moisture migrates out of the insulating paper and into the transformer oil. I mentioned above about heat being generated, and this occurs as the transformer voltage is powered up and down. As a consequence of the insulating paper being in immediate contact with the coils this heat breaks down the cellulose fibres of the paper into water and carbon dioxide. In fact, the heat reverses the natural photosynthetic process that formed the wood from which the paper was made.

In-line moisture sensors

In-line sensors, like ones supplied by Vaisala, monitor moisture levels and this gives an ongoing measurement of the state of the transformer oil. By inference from the moisture levels, this tells the maintenance engineers about the condition of the transformer and acts as an early warning of a potential failure.

Just as I said in my previous article, a random event, in this case an email from a mailing list, gets me into a diversity of interesting things in My World of Moisture.

If you would like to hear more about moisture in everyday life, please subscribe to my blog.

Welcome to my world of moisture

Kerry Page

I have been having our med. voltage oil xformers tested for a few years now and the moisture content has been acceptably low until this years test a couple of them spiked in moisture content. My question is if a transformer is powered down for too long after being energized for years will that give opportunity for moisture content to increase?

PeterMoir

Hi Kerry, Sorry for long delay. I more or less stopped blogging because of the pandemic and have just come back on to post. Did you get an answer to your question?

Kerry

No not directly. The company that was drawing the samples tested the 2nd time and they were telling me moisture level was still high and they wanted to take a third sample. I was suspicious that they might have contaminated the samples when they extracted them and I made sure that the 3rd sample was drawn on a dry sunny day. And when the report came back it showed a normal moisture level.

PeterMoir

Very astute, excellent. Just the thing I would have been suspicious about too.

Doug Elliott

Hello Peter:

I found your blog today while researching the effects of water in dielectric fluids. I enjoyed it and subscribed.

My company makes rapid LOD instruments, Moisture Balances to measure the moisture, TMV, in materials.

We also make a water specific analyzer as an alternative to Karl Fischer with comparable sensitivity, 1ppm, with no wet chemical reagents and fewer interferences.

If you are interested you can see our Vapor Pro XL on our web site http://www.broofkieldengineering .com.

I find the little bit of your work I have seen interesting.

Thank You

Doug Elliott

800-528-7411 x 1725

doug.elliott@ametek.com

PeterMoir

Hello Doug,

Thank you for your comment and kind words.

I know about Brookfield and just looked in more detail about your Vapor Pro XL. I think an instrument that gets rid of having to use the chemicals in KF is good news. I believe though that I have a much better way of analyzing moisture in pharma materials. I am the inventor and founder of Relequa’s Moisture Profiling technology. My passion is moisture and hence the blog.

Relequa does not have a reseller for the US. Would this be something of interest? I have been solving moisture issues in pharma for nearly 30 years and have a thorough understanding in this area.

Kind regards, Peter

Dr. Peter Moir

Consultant, CEO & Founder

Relequa Analytical Systems Ltd

Main Office:

Kilminion South, Ballinroad, Dungarvan

Co Waterford, Ireland

Mob: +353 (0) 86 805 1577

Email: peter.moir@relequa.com

Web: http://www.relequa.com

http://www.linkedin.com/pub/peter-moir/13/844/18

http://www.linkedin.com/company/relequa-analytical-systems-ltd

“Putting you in control of moisture”